First KPIs, Factors and AnyLogic

I focus first on the plant in Stuttgart-Zuffenhausen – Here is why.

The last weeks I read various reports, statements and analysis regarding Porsche and its production process. The supply chain is quite complex – for starting I would say too complex. That is why I decided to focus on the plant in Stuttgart-Zuffenhausen. It is the heart of Porsche. Of course, many things and factors which influence the risk of Porsche’s operations, and its sustainability will be missed out – at first at least. However, I must start somewhere.

Which KPIs and Factors I start with

When you start such kind of project, you have so many ideas, so many KPIs and factors in mind which could be interesting. It was hard picking the first KPIs and factors and leaving so many out of my first approach. Said that, I am still optimistic that the first KPIs and factors are still interesting for me and you to analyze and to understand.

Here is a short overview of the KPIs and factors:

Energy sources

Energy consumption and energy mix

Water consumption

Resources used (if information is available)

I am interested also in the analysis of different departments and process steps. However, I couldn’t find any publicly available data on that. That is why I will start with automotive standards which are publicly available. The more information I will gather, the more I can and will refine my model and analysis.

Why do I actually want to use simulation modeling?

Quote from AnyLogic:

“Simulation modeling solves real-world problems safely and efficiently. It provides an important method of analysis which is easily verified, communicated, and understood. Across industries and disciplines, simulation modeling provides valuable solutions by giving clear insights into complex systems.

Bits not atoms. Simulation enables experimentation on a valid digital representation of a system. Unlike physical modeling, such as making a scale copy of a building, simulation modeling is computer based and uses algorithms and equations. Simulation software provides a dynamic environment for the analysis of computer models while they are running, including the possibility to view them in 2D or 3D.

The uses of simulation in business are varied and it is often utilized when conducting experiments on a real system is impossible or impractical, often because of cost or time.

The ability to analyze the model as it runs sets simulation modeling apart from other methods, such as those using Excel or linear programming. By being able to inspect processes and interact with a simulation model in action, both understanding and trust are quickly built.”

What is AnyLogic?

“AnyLogic is the leading simulation modeling software for business applications, utilized worldwide by over 40% of Fortune 100 companies. AnyLogic simulation models enable analysts, engineers, and managers to gain deeper insights and optimize complex systems and processes across a wide range of industries.”

AnyLogic is used in various industries like Supply Chains, Manufacturing, Transportation, Warehouse Operations, Rail Logistics, Mining, Oil & Gas, Ports & Terminals and more.

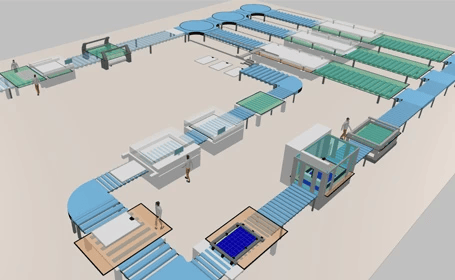

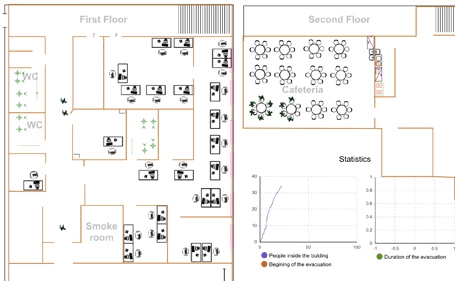

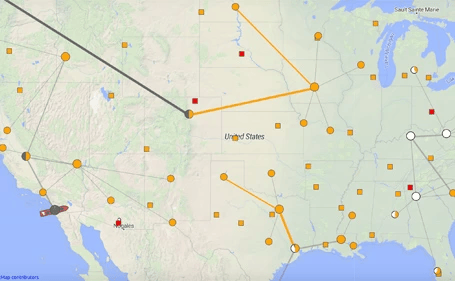

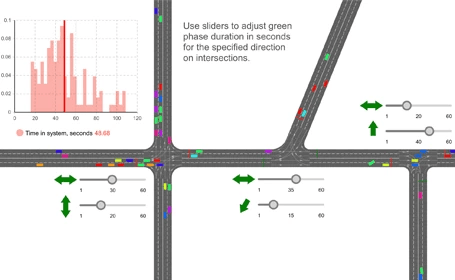

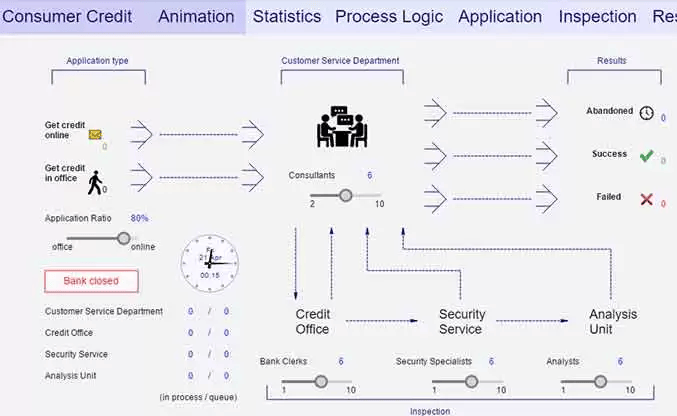

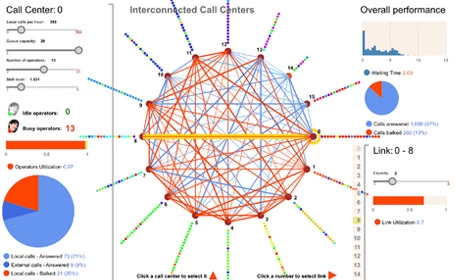

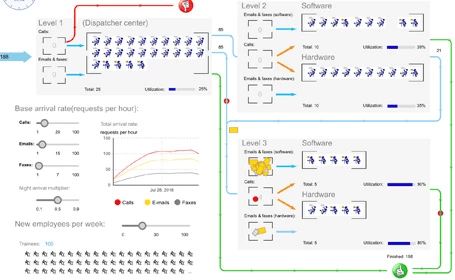

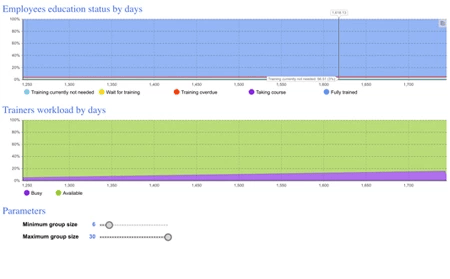

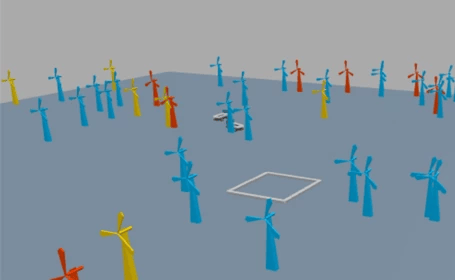

Here are some pictures, so you get a first impression:

Why did I choose AnyLogic?

I want to do the following:

Analyze systems (like facilities, production, government decisions) regarding business processes, their potential bottle necks and dependencies

Understand ESG relevant data and analysis regarding that

Understand and analyze supply chains

Run optimization experiments and compare the results or find the optimum

Want to find optima with various factors

Want to visualize the simulation in 2D and 3D but also with charts and dynamic process diagrams

For these requirements AnyLogic is the best simulation platform. It is versatile, up to date and keeps developing new features and functionalities.